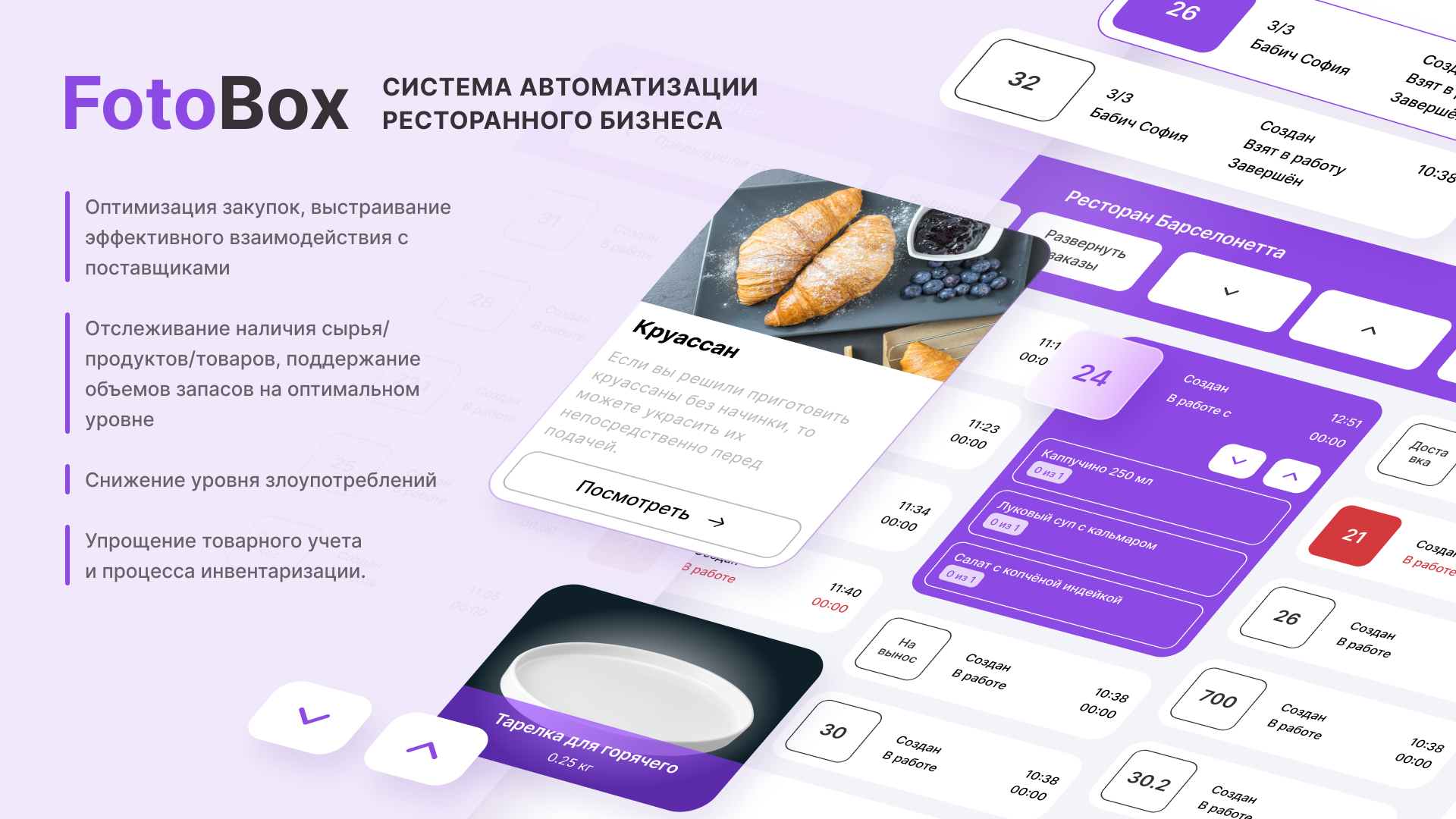

Automation system of restaurant business “FotoBox”

The most useful technical innovations appear when it is necessary to solve a burning problem. Such is the case with the “FotoBox”. The idea for this system arose as a result of attempts to solve one of the main problems of restaurateurs – the problem of theft, especially if the restaurateur owns several catering establishments, moreover, establishments located in other cities.

Of course, now “Photobox” is not just an application to control the activities of employees, but a comprehensive system for automating the restaurant business and is being finalized for sale in the markets of the CIS countries, as well as America and Eurasia.

However, it all started with the solution to the aforementioned problem.

To confirm this, tell the backstory of the owner of the London Restaurant Group Khvistani George, which started the development of “Fotobox”:

A few years ago Georgi first opened a restaurant outside of the city of Sochi. It was a project in the food mall DEPO Moscow. There was a realizer, a cashier, 3 chefs and a bartender at the site. The implementer was a person in whom Georgiy was 100% sure, however, as it turned out, one cannot be sure of anything and soon he discovered that the implementer was stealing.

And that was a big problem, because there was no way to prevent theft. Even if the retailer were changed. After all, any future employee had a chance to steal. Sure, there was a surveillance camera in the store, but in order to detect theft, it was necessary to sit and watch the recording 24 hours a day, which, accordingly, was not possible to allocate time for.

After what happened, Georgi began to think about a solution to this problem. As he saw it, everything was simple enough – only one manipulation had to be added to the salespersons’ activity, namely, pressing the button that sends a signal to the video camera (recorder) about the fixation of sales. Thus, it was possible to compare the number of sales and the number of sales recorded by the camera, as well as watch the cooking processes.

When Georgy started looking for this product on the internet, he realised that there was no such product and approached the ItFox company to help find something similar, however the market research brought no results and Georgy decided to implement the product himself, which was called the “FotoBox”.

Now this technology is patented by Georgy in Russia, is also in the process of obtaining a patent on the U.S. market and the European Union.

As we have said above, now “FotoBox” – is a complex automation system for restaurants and other catering companies. It consists of 4 main elements:

- Acceptance of goods

- Restaurant

- Food court

- hotel

Below we will consider in detail each module of the system, as well as talk about the benefits restaurateurs will receive after the implementation of this system in their establishments.

The “Receiving and production” module of the “PhotoBox” system controls:

- raw material/product/goods receipt;

- production

- movement between shops/warehouses/internal production.

How does this technically happen?

After receiving raw materials/products/goods from suppliers to the receiving warehouse an employee uses “FotoBox” to perform acceptance and create an internal document with a unique number on the POS-terminal.

The document contains all the information about the raw material/product/goods:

– name;

– price;

– date of the invoice;

– date of actual receipt;

– document number;

– weight and quantity;

– appearance (photo);

– actual temperature;

– the employee who received the goods.

At the same time, a unique barcode is created which masks the raw materials/products/goods. All the aforementioned information is attached to this barcode. The barcode label is printed on the printer and applied to the raw materials/products/goods.

Labeling of raw materials/products/goods in the process of reception is done quickly. The result – the goods with a unique UUID number.

Then the goods are transferred to the warehouse for safekeeping or to one of the workshops: billet, cold, hot, etc. The transfer is recorded by scanning a bar code twice: at point A (receipt) and at point B (warehouse or workshop).

This makes it possible to make sure that the raw materials/products/goods have been transferred in full and to see the time which has passed from the moment of shipment to the moment of reception in the workshop/warehouse (transportation time).

All data are transmitted to the server, from where they are transferred to other integrated accounting systems: 1C, R-Keeper, iiko, etc.

During the production of semi-finished products from raw materials/products/goods UUID, each individual semi-finished product is assigned a new unique barcode and a new internal document is created with the current information about this product UUID

– product/semi-product name;

– date of production;

– weight or quantity

– employee who made the product/semi-finished product;

– the creation shop.

The system allows you to track the entire “history” of the raw material from which the new semi-finished product was made.

Then the product/semi-finished product is sent to the warehouse/workshop/kitchen – also by scanning the barcode twice, at point A (transfer) and at point B (acceptance).

Module “Acceptance and production” solves the following tasks:

- optimization of procurement, building effective interaction with suppliers

- tracking the availability of raw materials/products/goods, maintaining stock levels at an optimal level

- Reducing abuses

- Simplification of merchandise accounting and inventory process.

Let’s move on to the next module of the “PhotoBox” system, namely the “Restaurant” module.

The “Restaurant” module of the “PhotoBox” system controls:

- consumption of raw materials/products/goods (in conjunction with the “Acceptance and Production” module);

- Compliance with cooking technology;

- adherence to the norms of the ticket-time;

- the speed and quality of service.

How does it happen technically?

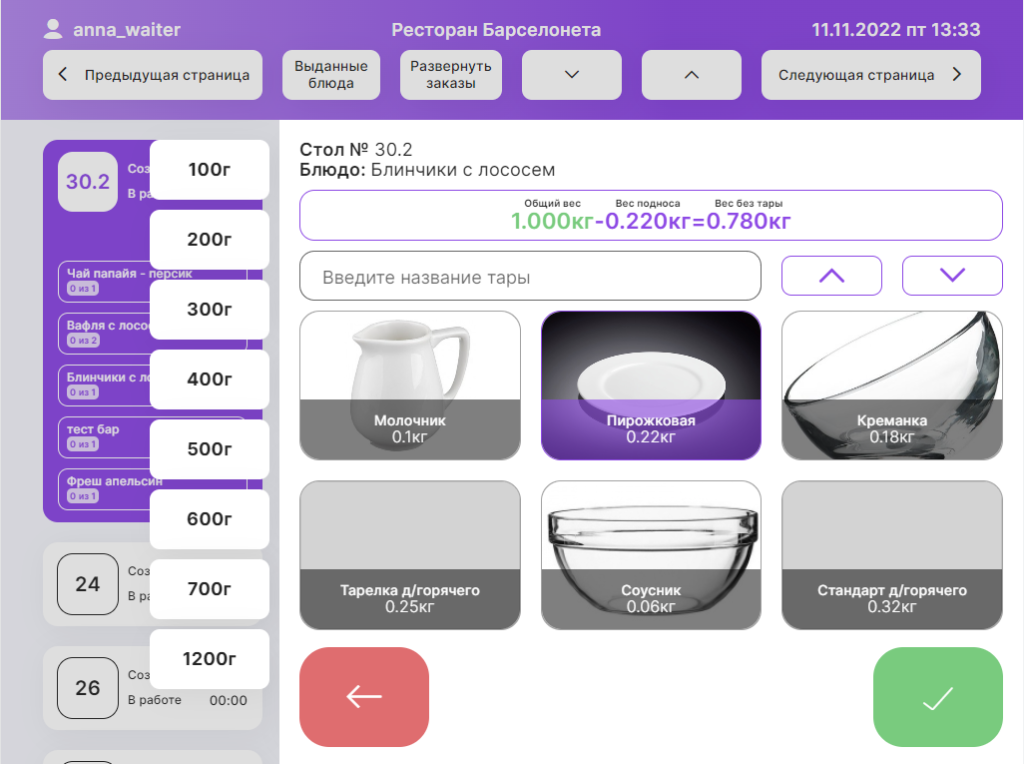

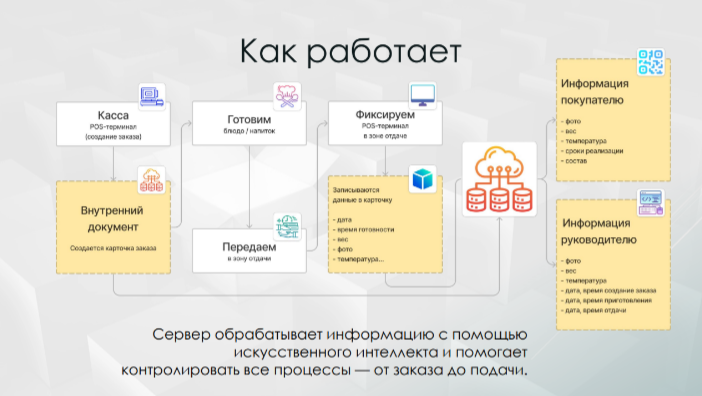

A waiter creates an order in the program (1C, R-Keeper, iiko, etc.) using a POS-terminal. The server of the FotoBox system processes information about the order (date, time, number of the table, dish, number of dishes) and creates an internal document – order card.

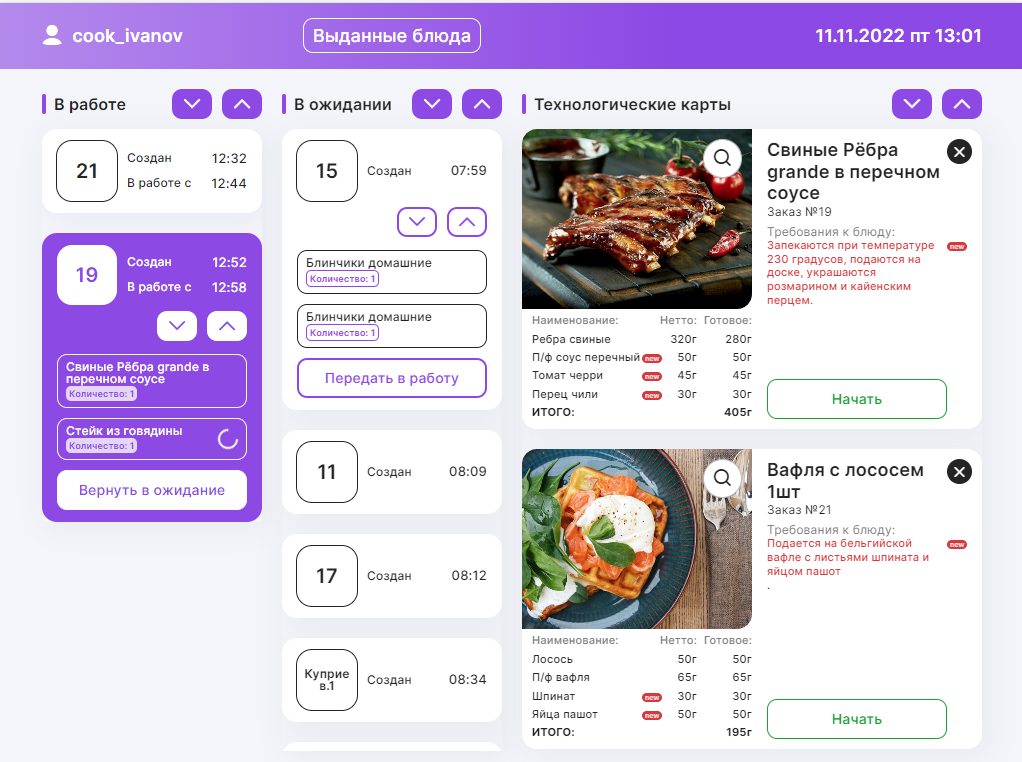

Chef sees on the monitor POS-terminal received orders and their order of delivery, at the same time on the POS-terminal chef of each shop his orders are displayed. Chef records the beginning of cooking, changing the status of the order in the system – “proceeded to cooking”, in POS-terminals chef and waiter, changing the status of the dish.

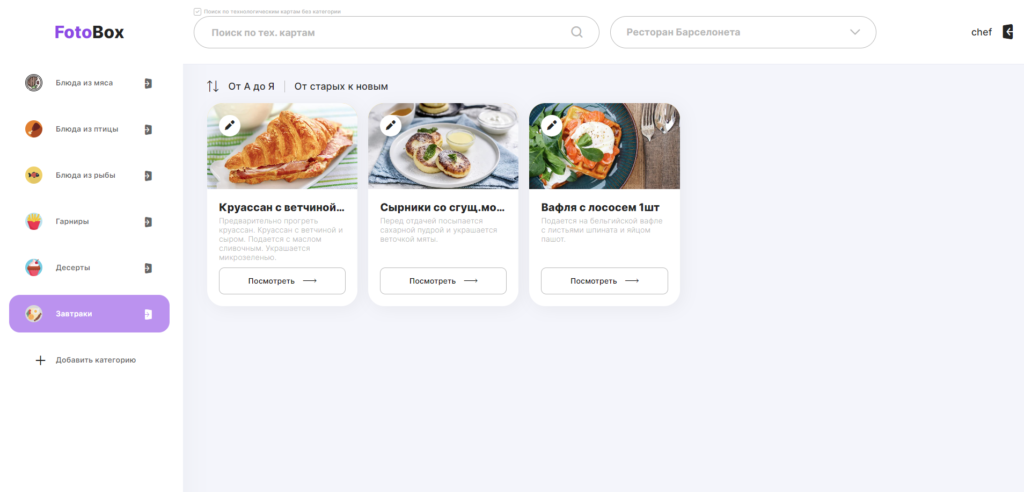

With the “Info” function the chef can get complete information about the dish: all ingredients, grammar and cooking technology, and see how a dish should look like prepared according to the standard accepted in the restaurant. Any changes made by the chef in the recipe are necessarily recorded with a note – the kitchen sees the actual information (instead of inconvenient paper STK).

The chef’s interface displays not only the lists of dishes in the “In progress” and “Waiting” statuses, but also the technological charts of the dishes taken in cooking. The changes made are highlighted in red and with the New tag. This allows the chef to navigate if the chef has added new ingredients or changed the serving style.

The chef interface allows the chef to fill in the recipe cards: enter dish description, cooking process, ingredients, upload a reference photo, assign a workshop.

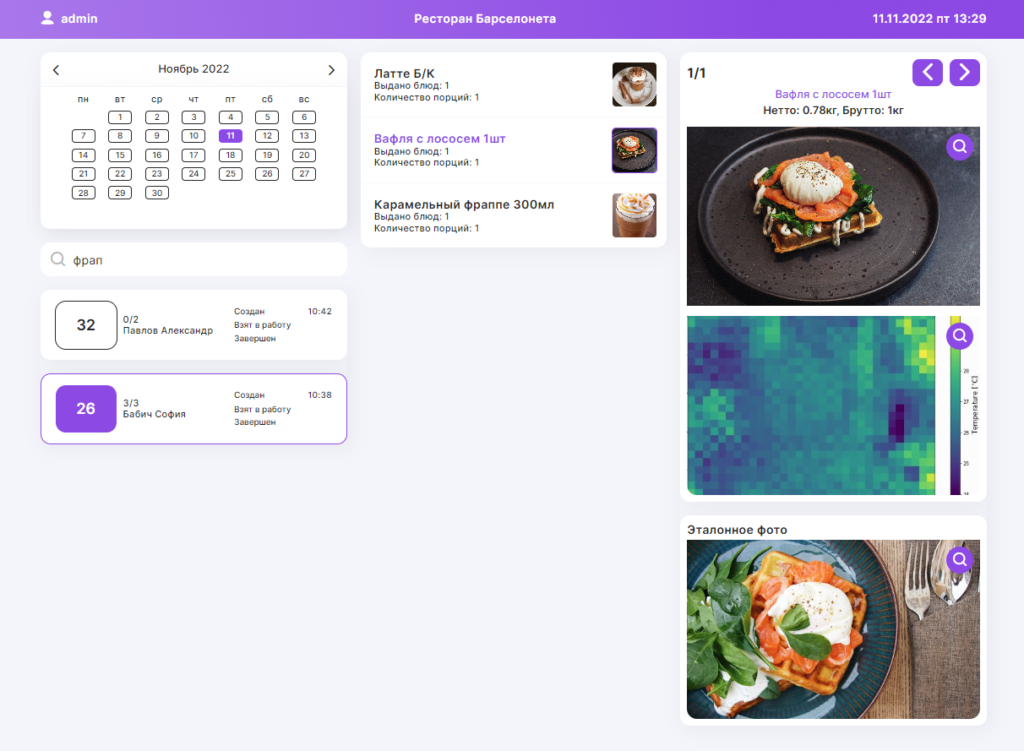

In the admin interface, you can track the quality of the food being dispensed as well as the speed of the service being provided. The photo captured by PhotoBox allows you to compare the dish given out with the benchmark, and the heat map will show whether the temperature of the dish given out corresponds to the established norms.

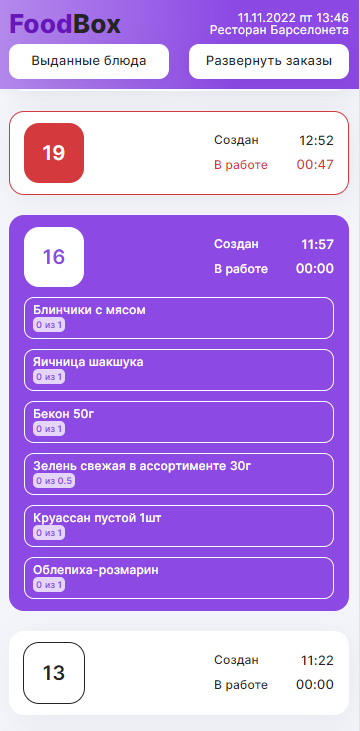

Prepared dishes are transferred to the distribution. The dispensing chef uses a POS terminal to record the readiness of food/drinks. The system changes the status of the order to “Dish ready” and notifies the waiter. He receives a notification on a special bracelet, picks up the finished dish using the “FotoBox” and notifies the system – “Dish taken. All information about the order – from its creation to serving – is stored on the server.

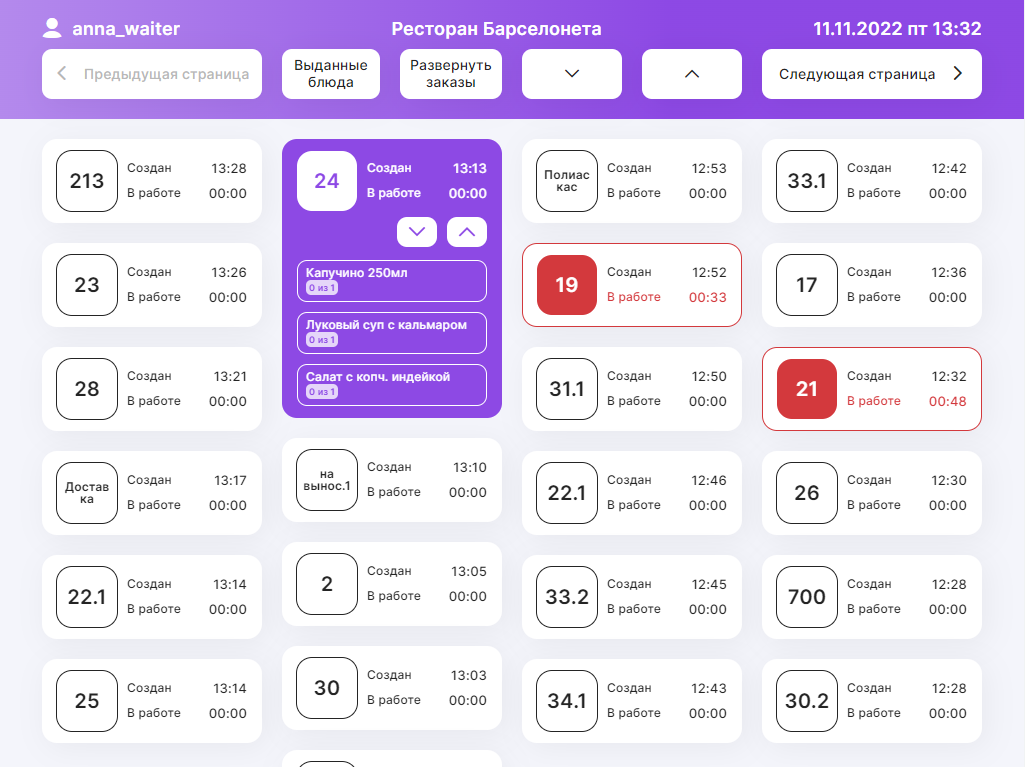

The waiter interface allows you to see a change in the status of the dish in the order and immediately give it to the guest. The order that exceeds the guest’s waiting rate will be highlighted in red.

Each dish goes through a special distribution “FotoBox”, thanks to which all characteristics of the prepared dish – weight, temperature, appearance – are recorded.

This allows the system to assess how dishes and drinks in terms of appearance, weight, temperature (visualized by zone with a thermal imaging camera) match the standards adopted in the restaurant. It also records the total time it took to prepare the dish and compares it with the internal 7 standards accepted. If there are deviations from the set standards, the system informs with a notification and marks in the program of the manager and chef.

The data can also be transferred to other integrated programs (1C, R-Keeper, iiko, etc.) for accounting and analysis.

When a dish is dispensed via the PhotoBox, it is easy to use the tare search function. Previously used containers are automatically pulled up for selection.

The guest receives a fiscal receipt with a QR-code. Using this code in the application he can see all the information about his order: the photo of the reference dishes and the photo of dishes from his order, the temperature of the zones, the time between the order and serving. The guest sees that the dish he ordered has been prepared exactly as he ordered it.

In order to improve the quality and speed of dispensing ready meals, a web version of PhotoBox for waiters was developed. This program allows the waiter to track the status of a dish and dispense it as soon as it has been prepared by the cook. Orders with deadlines exceeding certain standards are highlighted in red.

Conclusion: in the format of the restaurant system “PhotoBox” ensures compliance with the technology of food preparation and ticket-time standards, as well as accounting and write-off of raw materials/products/goods.

The next module of the “PhotoBox” system is very similar to the previous one, but has a number of distinctive features and is suitable for another type of catering enterprises, where self-service is present.

The “Food court” module of the “PhotoBox” system monitors:

– consumption of raw materials/products/goods (in conjunction with the module “Reception and production”);

– compliance with cooking technology;

– adherence to the norms of the ticket-time;

– speed and quality of service.

Let’s follow the business process in detail:

The cashier (or the guest himself) creates an order using a POS-terminal. The server of the FotoBox system processes information about the order (date, time, dishes/goods/drinks, quantity, amount) and creates an internal document of the order.

The guest receives a fiscal receipt with a QR code. By this code in the app he can see all the information about his order: time of registration, status of readiness, photo of reference dishes.

Employees of the kitchen can see on the monitor POS-terminal received tasks for the preparation of dishes and the order in which they are served, fix the beginning of cooking, changing the status of the order in the system.

Important: If the module “Acceptance and production” is available, all semi-finished products/products/items necessary for cooking dishes are accounted by barcodes – the system records their consumption.

Ready/formed orders are transferred to the distribution. Before serving, the parameters of the dishes: appearance, weight, temperature – are recorded with the help of “FotoBox”. This allows the system to assess how well they match the standards accepted in the company, and to compare the time it took to complete the order with internal standards.

All information about the order, from its creation to delivery, is stored on the server. Data can also be transferred to other integrated programs (1C, R-Keeper, iiko, etc.) for accounting and analysis.

All information about the order, from its creation to delivery, is stored on the server. Data can also be transferred to other integrated programs (1C, R-Keeper, iiko, etc.) for accounting and analysis.

Then the guest (or waiter, if this service is intended) takes the order. Using the QR-code from the fiscal receipt in the application the guest can also compare the finished dishes with the reference and see how long it took to prepare his/her order.

Conclusion: In the Food court format, the PhotoBox system ensures compliance with food preparation technology and ticket-time norms.

The next module is suitable for enterprises that outsource, for example, catering in a hotel.

The “Swedish Line – Hotel” module of the “FotoBox” system controls:

– consumption of raw materials/products/commodities (in conjunction with the module “Reception and Production”);

– compliance with the technology of preparing meals;

– compliance with the limits allocated for meals;

– the actual volume of cooked food and leftovers.

How does it happen technically?

The hotel catering service prepares an application for breakfast/lunch/dinner for a certain number of guests according to the estimated load.

The chef, in accordance with the request and the budget set per person, prepares and agrees upon a menu plan, and enters the data into the PhotoBox system. The system processes information about the order (date, time, dishes/goods/drinks, volume/weight/quantity, amount) and creates separate internal documents for items – for subsequent writing off of raw materials/products/goods.

Using the “Info” function, sous chef, distribution chef and cook can get complete information about the dishes: all ingredients, grams and cooking technology, see how a dish prepared in accordance with the accepted standard should look when served. Any changes in the recipe are necessarily recorded in the system – and the kitchen sees the current information (instead of inconvenient paper STK).

During the preparation of dishes according to the plan-menu – in the presence of the module “Acceptance and production” – all used semi-finished products/products/commodities, are accounted by barcodes – the system records their consumption.

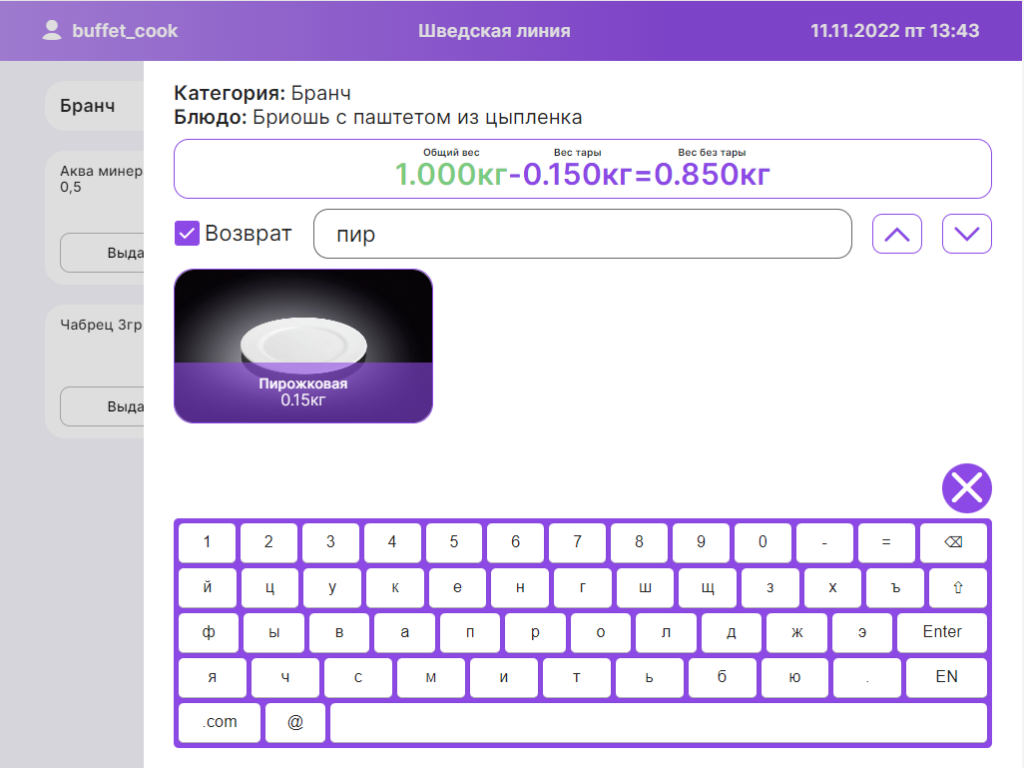

Before serving ready-made meals on the buffet line are fixed with “FotoBox”. Since the dishes are not served in portions, but in certain batches by weight or quantity, the system enters in advance the data on the containers and gastrotables (name, size, weight, etc.). This allows you to take into account the actual weight of the food at delivery without taking into account the dishes.

The process of capturing food dispensed via the Photo Box on the buffet line is also facilitated by the tare search function. The previously used containers for a specific dish are automatically suggested. The functionality is supplemented by the option to return a dish that has been dispensed.

If necessary, a return is made – for example, when the container with a hot dish is half empty, or when it is time to refresh the cold snacks – this moment is also recorded with “PhotoBox”: its name, volume/weight/quantity. This allows the system to calculate the actual return, that is, exactly how many portions the guests ate in the end. In addition, the system allows you to calculate and track the movement of products / goods / food past the issuance zone with additional sensors.

Conclusion: in the buffet format, the PhotoBox system provides statistics on the amount of food eaten, allows you to assess compliance with the limits allocated to food, compare the plan-menu and the actual amount of food/products/commodities served at the buffet.

Below we consider the main tasks, for the solution of which the customer turned to us:

1. optimization of procurement, building effective interaction with suppliers

2. tracking the availability of raw materials/products/goods, maintaining stocks at an optimal level

3. Reducing abusive practices

4. Simplifying merchandise accounting and the inventory process.

Let’s dwell on the solution of each of these problems in more detail

Optimization of purchases, building effective interaction with suppliers

The “FotoBox” system allows you to

– control purchasing prices and settlements with suppliers;

– track changes in contractual purchase prices in time;

– form orders with a fixed minimum inventory;

– build a scheme of procurement for the week / month ahead;

– Evaluate product quality by volume of write-offs for spoilage and waste;

– Avoid supplier or restaurant errors.

Track availability of raw materials/products/commodities, maintain stock levels at optimal levels

The FotoBox system allows you to:

– monitor the availability and movement of inventory;

– assess inventory in terms of commodity limits;

– observe the terms of storage and sale of products;

– minimize warehouse overstocking and product spoilage;

– make online inventories of raw materials/products at the point of return;

– Minimize inventory and improve product freshness.

Reduced abuse

The FotoBox system allows:

– Control the movement of products between workshops;

– trace channels of theft and abuse of staff;

– see how sparingly each employee uses products;

– avoid transferring/failure to report ingredients;

– apply personal liability for shortages;

– Minimize problems related to the “human factor.”

Simplify the merchandise accounting and inventory process

The FotoBox system allows:

– at any time “know” the location of raw materials and finished products;

– to completely eliminate errors when transferring data;

– quickly generate reports on the movement of inventory;

– create inventories of different detail;

– to account for all inventories, including opened cans and packages;

– switch from paper to electronic document management.

Next, let’s move on to the other modules of the Fotobox system and the tasks they solve.

In a restaurant format, the FotoBox system ensures compliance with food preparation technology and regulations, accounting and writing off raw materials/products/commodities, in other words, it solves the following tasks:

– control of the accuracy of the execution of food recipes;

– monitoring of violations in the production process and service;

– evaluating the actual speed of the staff;

– control of the speed of order fulfillment;

– maintaining the high standards adopted in the restaurant.

In the Food court format, the FotoBox system ensures compliance with food preparation technology and ticket-time standards. It solves the following tasks:

– monitors the violations in the preparation of food;

– evaluates the actual rate of staff work;

– monitors the loading of cash registers and the kitchen;

– controls the speed of execution of orders;

– maintains and increases the standards accepted in the company;

– increases brand awareness thanks to the app.

In the “Swedish Line – Hotel”, the FotoBox system provides statistics on the amount of food eaten, makes it possible to assess compliance with the limits allocated for meals, compares the plan-menu and the actual volume of dishes/products/goods served at the buffet, in other words it solves the following tasks:

– Controls the actual consumption of meals/products;

– supervises the observance of the technology of preparing meals;

– evaluates the speed of work of the staff;

– suppresses abuses and thefts by the staff;

– clearly accounts for leftovers to be written off;

– Evaluates the demand for dishes by item;

– Calculates the cost of a dish as part of the buffet;

– Maintains and raises standards adopted by the establishment.

Results:

In conclusion, let’s talk about the results that were achieved after the first phase of implementing the system.

At one of the public catering enterprises, the “Swedish Line – Hotel” module of the “PhotoBox” system was implemented, which allows at the time of shift closure to receive an online unloading, in which all realized dishes, as well as their balances, are automatically accounted for. After entering a dish into the program staff has no opportunity to make changes to the documents (only through a request for correction). Thus, the staff, first, got rid of manual paperwork, and secondly, it is no longer possible to take out less food or replace products. By the way, to exclude the abuse of working meters and sneaking food, bypassing the distribution area, use additional external sensors and a camera, which makes such abuse impossible.

Moreover, all financial information on the closing of the shift is immediately transferred to the accounting department, which greatly speeds up and simplifies the accounting process.

Outsourced customer (hotel) also receives a database of issued dishes with all necessary parameters (quantity, weight, temperature, etc.). Thus he can control the absence of abuse, which allows to increase loyalty, as well as quickly and transparently solve all disputes.

Also, using the analytics provided by “Photobox” allows you to quickly edit the menu plan (portion per person) and optimize costs. At the moment, due to the reduction of abuses and optimization of the menu plan, the saving was 18.9%; in the future, the customer expects to increase the savings to 30%.